-40%

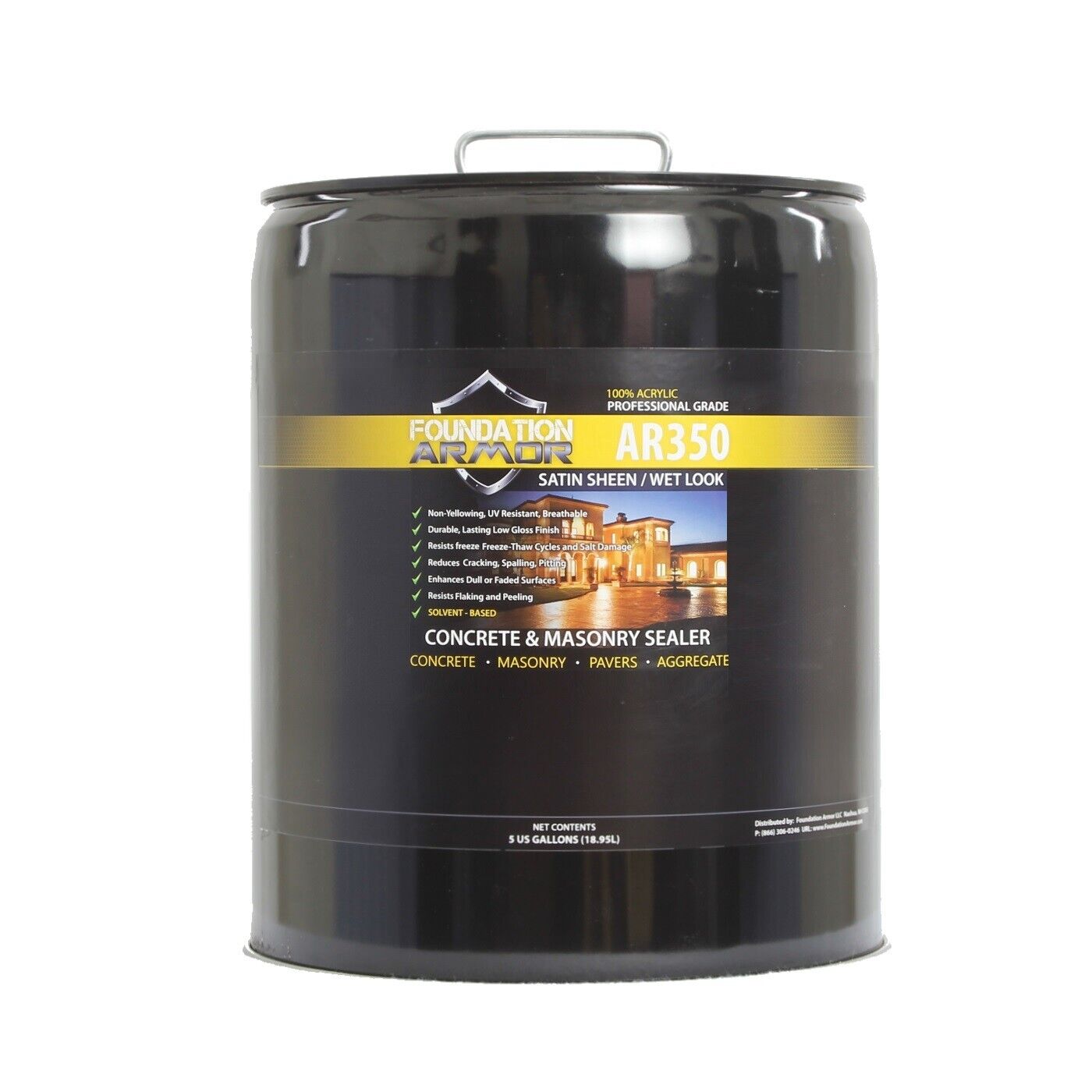

Armor AR350 Solvent Based Acrylic Low Gloss Wet Look Sealer - 5 GAL

$ 118.79

- Description

- Size Guide

Description

The Armor AR350 is a solvent-based acrylic sealer designed to enhance, seal, and protect concrete and paver surfaces. It will darken the surface and enhance any dull and faded coloring, and protect the surface with a durable low gloss surface film. The Armor AR350 is a fantastic sealer if you are looking to bring out dull and faded surfaces, and enhance surfaces with a low gloss wet look finish.The Armor AR350 is made from high quality, non-recycled, US manufactured resins. It is non-yellowing, breathable, and low VOC. The protective low gloss film will reduce damage and deterioration caused by surface abrasion and water absorption including cracking, spalling, pitting, dusting, and the growth of mold, mildew, and algae.

Benefits:

Will darken the surface to make it look wet, bringing out any dull and faded coloring

Protective surface film will reduce damage and deterioration caused by water absorption and surface abrasion

Protective surface film will reduce the growth of mold, mildew, and algae on the surface

Made from non-recycled US manufactured resins

Easy to apply, easy to maintain, easy to re-coat

UV resistant, breathable

Uses:

The Armor AR350 is a great choice for a variety of interior and exterior concrete applications, including:

Pool decks and patios

Driveways, walkways, and stairs

Garage and basement floors

Retail and shop floors

Warehouse floors

Much more!

The AR350 can be applied to a variety of interior and exterior concrete surfaces, including:

Stamped concrete

Poured and broom finished concrete

Exposed aggregate concrete

Concrete pavers

The Armor AR350 is designed specifically to be used on unsealed concrete and concrete pavers. It can also be applied to concrete and concrete paver surfaces previously sealed with a solvent based acrylic. The Armor AR350 should not be used to seal clay brick, red Chicago pavers, flagstone, slate, or natural stone. If you are looking to seal clay brick, red Chicago pavers, flagstone, slate, or natural stone, consider instead of the Armor WL550 or the Armor SX5000 WB.

The Armor AR350 can’t be applied over any other film forming sealer, other than a solvent-based acrylic sealer. It can’t be applied over a water based acrylic, an acrylic latex, a paint, epoxy, or urethane.

Appearance

When applied in clear, the Armor AR350 will darken the surface to bring out the natural coloring the concrete or pavers, and seal it with a transparent low gloss finish. When applied in a color, the Armor AR350 will cover the concrete or pavers like a paint (opaque).

The actual level of gloss and enhancement received will depend on the type and age of the surface, age, porosity, condition, applicator, application method, and amount of material applied. For an accurate representation of what your surface will look like once sealed, we suggest applying the product to a test area first.

Product Life

When properly applied, the Armor AR350 can provide up to 1-3 years of life on an exterior surface before the need to recoat, and up to 2-7 years of life on an interior surface.

While the Armor AR350 is designed to out-last and out-perform similar products on the market, there are several factors that can impact actual product life including the severity of surface abrasion and level of foot traffic, the porosity of the concrete or pavers, and the amount of resin build-up on the surface. Some surfaces need to be sealed every year, while others can go a few years without sealing.

How To Apply:

The Armor AR350 can be applied with a 3/8-1/2” nap roller, or an acetone/solvent resistant HVLP sprayer with Viton seals. For a consistent wet look and low gloss finish, apply two coats spaced 24 hours apart.

Time Of Day

The Armor AR350 should only be applied in the early evening (around 5 PM or later) when air and surface temperatures are declining, and when the sun is no longer positioned over the surface.

Surface Preparation

The Armor AR350 should be applied to a completely clean and dry surface. If the surface was cleaned with water or pressure washed prior to application, allow the surface to dry for at least 24 hours before sealing. While the surface may appear dry and feel dry to touch, water below the surface trapped in the pores can cause the same issues. While pressure washing the surface is typically sufficient, spot treatment may be necessary for deep or older stains.

The Armor AR350 is designed specifically for use on unsealed porous concrete and concrete paver surfaces, as well as concrete and concrete pavers previously sealed with a solvent based acrylic. Do not apply this product over a surface previously sealed with a water based acrylic, or any other type of film-forming sealer. If the surface is smooth troweled, or does not easily accept water, acid etching may be required prior to applying sealer. It is always suggested to apply the Armor AR350 to a test area to verify absorption, coverage, compatibility, and project suitability.

Note About Sealing Pavers:

Please note, the Armor AR350 is not a bonding agent. Do not apply the Armor AR350 over loose sand between paver joints because it will not harden or seal the loose sand. The Armor AR350 can be applied over the pavers directly, or the pavers and polymeric sand (if the polymeric sand is newly installed, wait 7 days before sealing), but it can’t and should not be applied over loose sand.

Mixing Color Packs:

Do not exceed more than 6 ounces of color per gallon of sealer. Stir color well before adding to sealer, then once added to sealer, stir again, ensuring color is evenly mixed. When applying the AR350 in color, it will cover like a paint, completely opaque.

Adding Non-Slip:

For best results, apply the Armor non-slip additive with an appropriate hand-held broadcast spreader. When applying the second coat, add the non-slip additive to the coating using a broadcast spreader, and back roll to encapsulate the non-slip additive.

For complete application instructions and safety data, please refer to the Documents tab.

Coverage:

Porous Surfaces: Up to 175 FT2/gallon in one coat.

Smooth Surfaces (once properly prepped): Up to 200-225 FT2/gallon in one coat.

Coverage will vary depending on porosity, surface condition, application method, and the amount of material applied by the applicator. The above coverage rates are estimates and will vary. Two coats are suggested for even coverage and appearance.